In the plastics industry, knowing the identification codes and labels of materials is fundamental.

For manufacturers, recyclers, and conscious consumers alike.

These codes allow identification of the type of plastic, its properties and the correct way to reuse or recycle it, avoiding confusion and improving efficiency in waste management.

In this month’s blog post, we’ll explain how to interpret these labels, their importance, and how they contribute to a sustainable circular economy.

What are plastic identification codes?

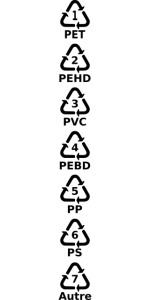

Plastic identification codes are standardized symbols.

Generally a triangle of arrows with a number inside, which indicates the type of polymer a product is made of.

This system was developed by the Plastics Industry Association and is used internationally to facilitate recycling.

Each number corresponds to a specific type of plastic:

PET or PETE (Polyethylene Terephthalate)

Used in beverage bottles and food containers.

It is recyclable and widely accepted in recycling plants.

HDPE (High-density polyethylene):

Found in detergent containers, plastic bags, and some toys.

It is durable and recyclable.

PVC (Polyvinyl chloride)

Common in pipes, linings, and cleaning containers.

Its recycling is more complex.

LDPE (Low-density polyethylene)

Supermarket bags, plastic films and flexible wrappers.

Recyclable, but not always accepted at all centers.

PP (Polypropylene)

Caps, yogurt containers and food containers.

It is heat resistant and recyclable.

PS (Polystyrene)

Food containers, disposable cups and packaging.

Its recycling is limited and usually requires specialized management.

Other (O or PLA)

Plastics such as polycarbonate, nylon or bioplastics.

This group is heterogeneous and its recycling depends on the specific facility.

How to read plastic labels

In addition to the number, many labels include additional information, such as:

-

Recycling symbols:

They indicate whether the packaging is suitable for recycling and under what conditions.

-

Instructions for use or safety:

For example, “food safe” or “not suitable for microwave use”.

-

Marks of origin or certification:

Some recycled plastics carry seals that guarantee their purity and traceability.

Correctly interpreting these labels allows manufacturers and recyclers to sort plastics efficiently.

This avoids the mixing of incompatible materials that could compromise the quality of the recycling.

Importance for the circular economy

Knowledge of identification codes is essential to ensure efficient and high-quality recycling.

Post-industrial plastic, carefully selected and classified according to its type, is processed while maintaining its original properties.

Ready to be reused in new products.

This reduces the need for virgin plastic and contributes to the reduction of waste and pollution.

For consumers, knowing these codes helps to properly separate household waste.

And to support responsible recycling.

In addition, it allows you to choose products made with certified recycled materials.

Promoting demand for quality reusable plastic.

Practical tips

-

Always check the number inside the recycling triangle before disposing of a container.

-

Check your local recycling regulations, as some types of plastic may not be accepted in your region.

-

Look for guarantee seals if you buy recycled material, ensuring that it meets purity and safety standards.

-

Avoid mixing different plastics when recycling, as this can hinder effective reuse.

Correctly interpreting the labels and identification codes of plastics is key to optimizing recycling, reducing waste, and promoting a sustainable circular economy.

Both manufacturers and consumers play a crucial role.

Companies can guarantee the purity and traceability of recycled plastic.

While consumers can separate and properly dispose of the packaging.

Understanding and applying these codes is a simple but vital step towards a more sustainable and efficient world in the use of plastic resources.